CHILLED WATER PLANT OPTIMIZATION

The chilled water plant is often one of the most complex systems within a building. It’s also typically one of the biggest energy users. And today, almost all chilled water plant controls are provided by controls companies who are often not well-versed in the intricacies of chilled water production.

Global footprint. Proven results.

Our team has delivered over 300 chilled water optimization projects across the globe, with a focus on performance and efficiency. Using this expertise, our Central Plant Energy Conservation System (CPECS) delivers unmatched efficiency and reliability for chilled water production, using real-time control algorithms that constantly seek to minimize the energy consumed within the plant. This regularly results in 15%-30% efficiency improvements over standard automation systems. Our model-based approach ensures stable, reliable, and optimized control.

Model S

Optimize any plant by integrating CPECS directly into your building automation system. Optimize any plant by integrating CPECS directly into your building automation system—no need to remove or replace existing controls. We will work alongside your controls team to ensure seamless operation and optimization of your chiller plant.

Model T

A standalone solution.

CPECS Model T is an automation system that provides standalone control (automation and optimization) of the chilled water plant. All inputs and outputs to and from the field hardware are connected to CPECS. Logic within CPECS is programmed to offer full control of the entire central plant to ensure efficient, reliable production of chilled water.

No building automation system integration is required within the plant room.

Model CPM

A total controls solution.

CPECS Model CPM is a total controls solution, ensuring efficient operation and superior performance. Its advanced automation and controls strategies contribute significantly to the reliability, efficiency, and overall operation and performance of the chilled water plant room. Model CPM provides all input and output requirements to control chillers, pumps, and fans within the plant room envitornment.

Using industry best-practices, we have developed several “no single point of failure” and “fail-to-run” solutions tailored to data center and other mission critical applications”

CPECS Model Comparisons

An optimization system that:

- Can optimize operation of water-source and air-source heat pumps (two-pipe and four-pipe)

- Is tailor-made for your plant

- Prioritizes your needs (energy, CO2, demand response)

- Optimizes all compressor types

- Integrates heat recovery, heat pumps, and more

- Works with all chiller brands

- Is not subscription-based

- Delivers proven, verifiable results

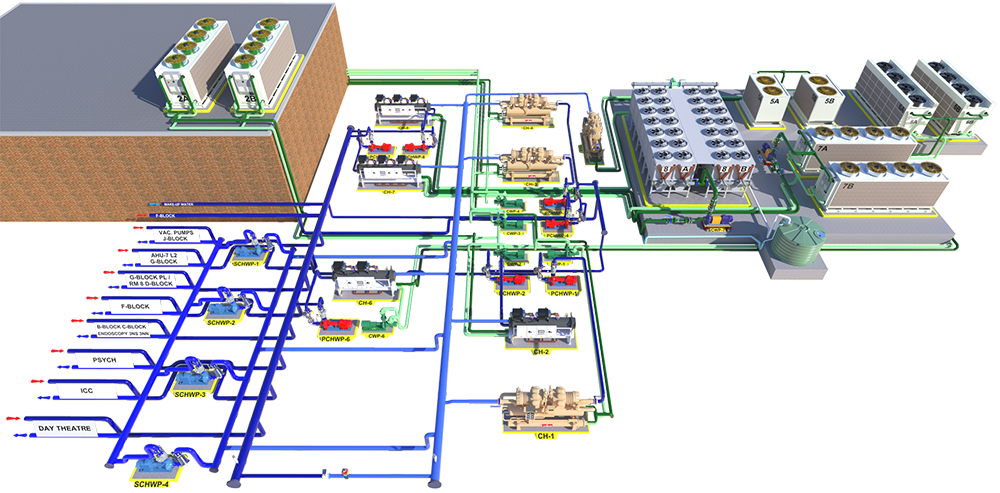

- Has built-in customized graphics, to reflect the actual layout of the plant room

- Can integrate the boiler plant

Want to rent Smardt chillers?

Contact a specialist to learn more about our rental services.